Impact of Zero Loss Centers on Kenyan Mango Farmers

By: Amos Kioko

The Rockefeller Foundation ConsultantKenya typically produces about 750,000 MT of mango annually and the volume of production has been increasing. The increase in production is due to:

Increased demand for fresh and processed mango from a growing urban population which has a higher purchasing power

Access to regional and international markets

Increased profits driven by a low cost of production and high market price

Adoption of post-harvest loss reducing technologies by mango farmers

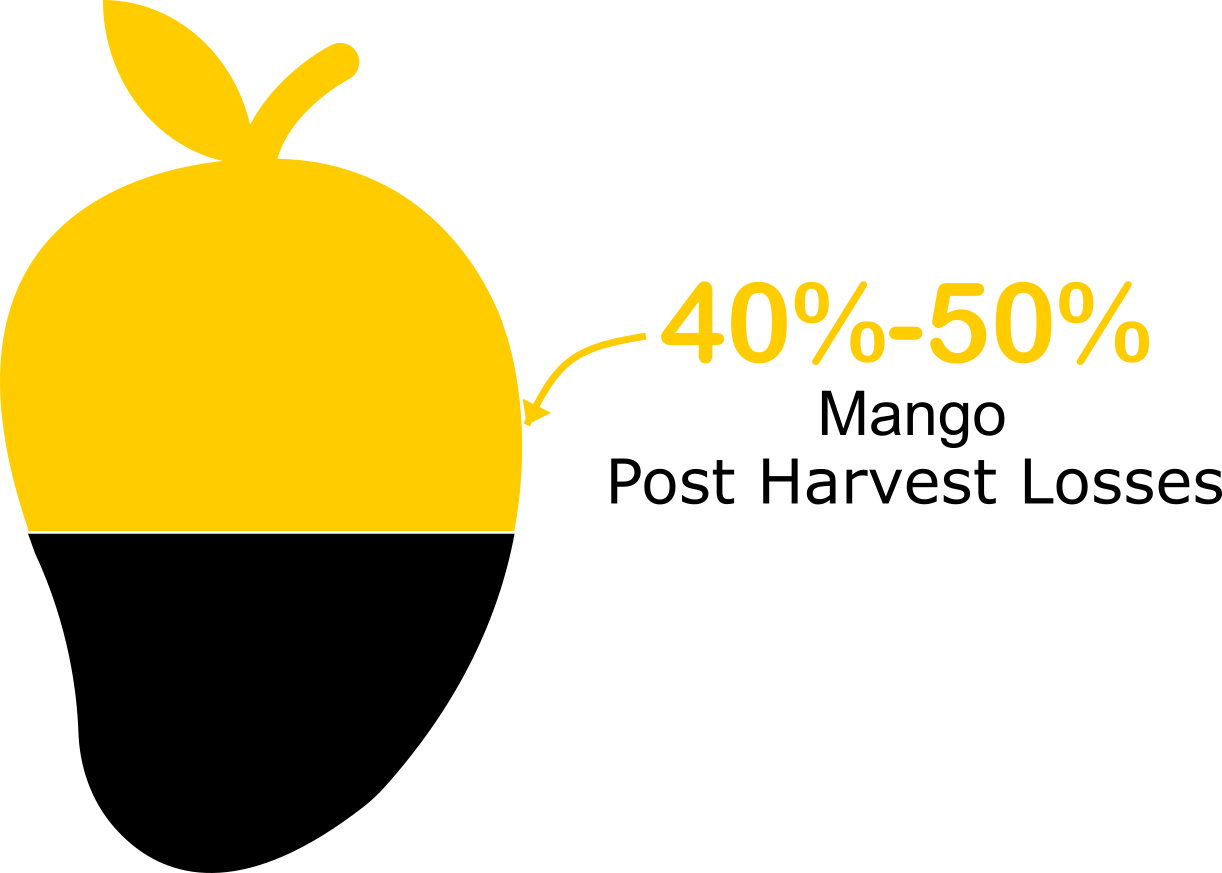

However, when the mango season is at its peak (November - March), an oversupply dampens the farm gate price. During the mango season, a kilogram of the fruit sells for less than $0.10 at the farm gate. While in the urban markets the price can be more than 10 times higher as mangoes sell for $1.00 per kg or more. Furthermore, traders who are the main suppliers of fresh market mangoes in urban centres buy the produce at low prevailing market prices. This situation forces mango farmers into being “price takers,” with no room to negotiate for better terms. If they do not accept the prices offered, their produce is left to rot in the farm – resulting in high post-harvest losses of about 40% - 50%.

To address this issue, Zero Loss Centres were estabished in Kenyan mango growing regions. These centres were part of the YieldWise initiative and The Rockefeller Foundation, the University of Nairobi Postharvest Research Team, and Technoserve Kenya partnered to found them. The centres are owned and run by farmer groups and are equipped with low-cost cold storage technologies (such as the Coolbot Cold Room, Charcoal Cooler and Zero Energy Brick Cooler). These technologies collectively have a storage capacity of 10 – 12 MT of mangoes and can store the mango produce for an extended shelf life of up to one month. These technologies have enabled farmers to aggregate, store and sell their produce at better prices when the mangoes are out of season as well as reduce mango losses that would have occurred if there was a glut.

In addition, the centers are equipped with juice processing and drying facilities. Farmers are now processing the surplus mangoes into shelf-stable, value-added and nutritious-safe products such as pulp, juices and dried mango chips. Besides extending the shelf life, the value-added products fetch better prices for the farmers. Unpublished data shows that a ton of fresh mangoes aggregated at the zero loss center can fetch $150 to $250 per ton while at farm gate price, a ton of fresh mangoes goes for less than $100. On the other hand, ready to drink juice can fetch $600 to $1,000 per ton while dried mango chips can fetch $1,000 to $3,000 per ton in the local market[1].

As we had envisioned, the Zero Loss Centres have reduced losses drastically, since all the produce aggregated is sold as high-quality, value-added, safe and nutritious products. Farmers are able to access domestic and international markets paying a premium price for quality and consistent products. In addition, the centres are hubs of excellence that provide demonstrations and learning opportunities on post-harvest management. Delegations from other countries in Africa have visited the centres to benchmark and replicate the model, and other actors in the supply chain get training in good post-harvest handling practices and small-scale processing of fruits and vegetables.

The YieldWise investments in the Zero Loss Centres clearly demonstrates evidence of impact and a case for governments and other actors to invest in post-harvest loss reducing innovations. The benefits to farmers, the environment and a growing urban population with access to safe, nutritious fresh mangoes and mango products cannot be underestimated.

[1] Ambuko et al. 2019

Mango images for lost post-harvest - Designed by Ery PrihanantoMango image for the title section and price comparison - Obtained from rawpixel.com